AK 640 SA

Ihr Kontakt

Doppstadt Umwelttechnik GmbHSteinbrink 13

42555 Velbert

Deutschland

Telefon: +49 2052-889-344

E-Mail: used(at)doppstadt.de

Internet: doppstadt.de

Spezifikationen

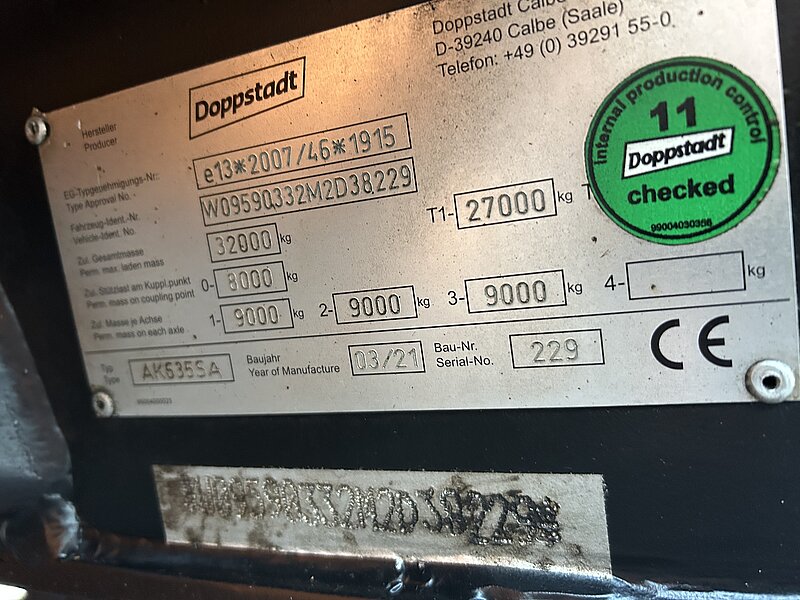

| Hersteller | Doppstadt |

| Modell | AK 640 SA |

| Baunummer | #229 |

| Procedures | Feinzerkleinerer |

| Baujahr | 03/2021 |

| Betriebsstunden | 2954 |

| Standort | D-42489 Wülfrath |

Produktinformationen

equipment:

Basic package AK 640 SA

| Doppstadt AK640SA |

| Standard equipment AK 640 SA - Mercedes / MTU -Diesel engine 6R1500, 480 kW at 2.000 U/min - semitrailer chassis with 3 axles, license for 80 km/h on public roads - brake system with ABS brake and lighting acc. to EEC directive - tyres 385/65 R22.5 - permissible total weight 32,000 kg - hydraulically adjustable jack legs - splashguard (inside and at side of fenders) - Mercedes/MTU Diesel engine 6R1500, 480 kW at 2,000 rpm, complies with emission standard EUROMOT V" - additional hydraulic connection 20 l/min - load-sensing material feeding incl. automatic scraper floor reverse " - independent drive for infeed roller and scraper floor (twin drive) - fuel tank 2 x 450 litres - infeed drum: length 1,690 mm, diameter 510 mm, with fitted tooth segments" - four-row flail drum with 36 free-swinging cast-steel flail holders and replaceable flail tips - standard equipment: flail tips "carbide plus - deflector with teeth - central lubrication points - electric pump for control of the cylinder functions (e. g. rear basket open/close and ' support up/down,folding of the rear conveyor, release of the hydraulic self-propelled drive) at engine standstill - 24 Volt electrical control - additional control box at rear part of the machine - hydraulically opening fine-shredding basket Multimesh (mesh sizes between 30 and 280 mm, grading on request) incl. hood - Rear conveyor: belt length 7,500 mm, belt width 1,500 mm, discharge height 5,200 mm, hydraulically foldable and lowerable between 39 and 30 degree, with antimagnetic central part - lower conveyor: belt length 3,800 mm, belt width 1,400 mm - damping facility for external water supply - scraper floor with 72 scraper bars - wear protection at drum area - Reinforcing panels at the feeding hopper (from wear resistant steel) on both sides for side wall" - radio remote control complete - fire extinguisher - acoustic start indication - Doppstadt-Telematic-System - paint: RAL 2011 orange In case of delivery of optional equipment the corresponding standard equipment will be dropped. |

additional equipment:

| Hydraulic self-propelled drive |

| Scraper floor chain lubrication right-hand and left-hand side |

| Overband magnet -Neodym- |

| Frame for overband magnet |

| Centralized lubrication |

| protectiv plate for engine room ( material hardox ) |

| LED - Lighting kit: Engine compartement and rear |