Outstanding efficiency

The new Inventhor 6.2 stands for more efficiency, easy handling, good accessibility maximum uptime, due to the VarioDirect Drive system:

- high production rates

- low fuel consumption

- self protection against damage

This is how it achieves unmatched low operating costs – even in case of difficult tasks.

Right to the point

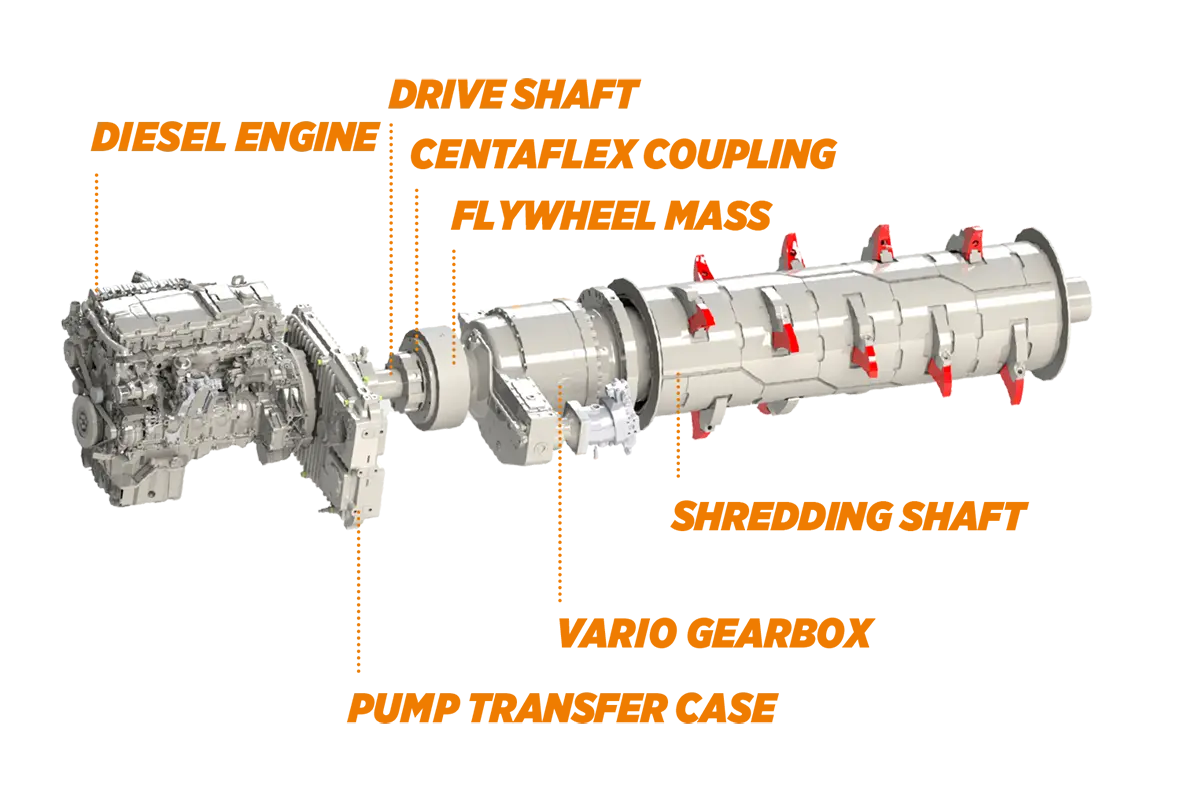

The patented VarioDirect Drive copes with nearly all kinds of shredding tasks with excellent results. It transmits the driving power variably and continuously to the shredding shaft. Therefore, the Inventhor 6.2 combines the flexibility of a hydraulic drive with the efficiency and torque of a direct drives.

- flexible rpm adjustment of the shaft independent of the engine rpm

- intelligent reaction behaviour in case of overload

- efficient self-protection thanks to the automatic stop and reverse of the shaft

- dynamic starting behaviour even under full shredding chamber

- economical shredding in different material programs

Anywhere performing anywhere

Inventhor 6.2 is perfectly prepared for any challenge in the recycling of a large variety of materials. It covers a wide range of applications in the field of pre-shredding.

- configurable shredding system with quickly replaceable teeth

- pre-settable processing programs for quick and intuitive operation of up to four different applications

- removable hopper extensions for lower loading height

- the total volume can be extended to approx. 8 m3 via hopper extensions

You can open the comb holder wide. This guarantees you good and, above all, safe access to the shredding chamber. The comb bar with comb teeth can be completely removed. If you are using a second comb bar, you can fit it with new comb teeth in the workshop beforehand. The limiter is simply inserted into the mounting. All together, this significantly reduces your changeover times.

Therefore, the Inventhor 6.2 is the ideal combination partner for robust separation solutions, where the finished product is made in one pass, so only touching the material once.

For more detailed information, please download the current product brochures.

The material feed system of the INVENTHOR 6.2 ensures that the shredding process goes smoothly. It has a hopper volume of 4.5 m³. The total volume can be extended to approx. 8 m³ using removable hopper extensions.. Thanks to the low loading height and a loading width of over 3.3 m, loading with wheel loader buckets is also operator-friendly. The folding hopper can either be loaded and tilted batch-wise or it can be set at a suitable angle such that the material automatically slides into the shredding area.

Powerful, dynamic, and ready to use anywhere you need it! The Inventhor 6 shreds with high efficiency – whether green waste, industrial waste, waste wood and a lot more. And, of course, in perfect teamwork with the Doppstadt Selector 800.2 with SWS 800.2 spiral shaft screen within complete material processing lines.

With Doppstadt, you react smart to the increasing demands on recycling quotas – for example with the combination of Inventhor 6 and Selector 800: They process Waste wood or Green waste as well as Industrial waste in one work step. For this purpose, the Selector screens out the oversized particles and returns them back to the shredding unit. Furthermore, it is driven by the additional hydraulic connection of the shredder. A total of 5 different spiral shaft decks for the selector and 2 Shredding systems for the Inventhor 6 enable individual configurations for any requirements.